Specialized wire bonding and die bonding solutions

About Wire and Peg Bonding

Bonding with heat or at room-temperature

Diverse bonding compatibility for a wide range of metals, alloys and applications.

Wire bonding has evolved into a highly controlled process since its adoption in the 1950’s.

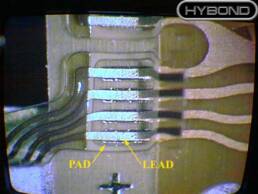

Today, it is widely used for interconnecting semiconductor chips to package leads, connecting disk drive heads to pre-amplifiers, and various applications that enable smaller, smarter, and more efficient devices.

Wire bonding involves attaching a small-diameter soft metal wire, such as Gold (Au), Aluminum (Al), Copper (Cu), Silver (Ag), Platinum (Pt) or alloys like Palladium-Silver (PdAg) and others to a compatible metallic surface without solder or flux.

Explore the three most common processes:

Thermocompression Bonding

Thermocompression Bonding is a wire bonding process that involves the use of force, time, and heat to achieve a bond between two materials through inter-diffusion. This technique is often associated with ball bonding and utilizes gold wire and a gold bond surface. Unlike other bonding methods, thermocompression bonding does not involve ultrasonic vibration of the wire.

The process starts by heating the wire, which is then pressed against the hot surface with high force for a specific duration to achieve the bond.

Thermosonic Bonding

The Thermosonic Bonding wire bonding process combines the use of force, time, heat, and ultrasonic energy to create a bond between two materials. During the process, at room temperature, or heated, a wire is pressed against a hot surface with a relatively low force and vibrated at ultrasonic frequency for a limited time to create the bond between wire and surface. This process is normally done with gold wire and a gold bond surface. Gold wire ball bonding is traditionally most associated with thermosonic bonding, however, thermosonic wedge bonding of wires and ribbons is also common. Another material, Platinum, can also be used for standard thermosonic wire bonding. Copper and aluminum wire can also be used however is important to keep these materials from oxidizing by using a cover gas.

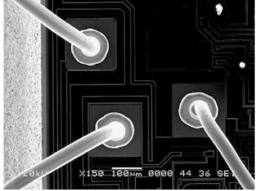

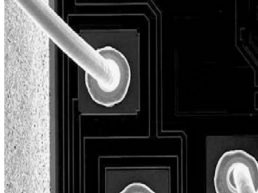

Gold Ball Bonding

Gold Ball Bonding is a wire bonding technique that in its initial stages creates a ball or sphere at the end of a gold wire. The ball formation is achieved using an Electronic Flame Off (EFO) to create a spark to melt the wire. The use of EFO was instituted as it is safer than traditional open hydrogen flame methods.

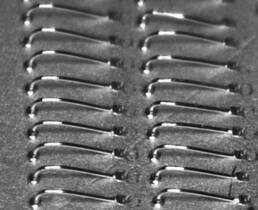

Bump Bonding or Stud Bumping

Bump Bonding, also known as Stud Bumping, is a variation of Gold Ball Bonding where only the bump is bonded to a surface without extending the wire. This technique is commonly used to create gold bumps on dies, often for subsequent flip-chip bonding, or to connect surfaces that are at 90-degree angles with close contacts

Wedge Bonding

This technique uses force, time and ultrasonics with the bonding surface at room/ambient temperature to create bonds. Initially designed for aluminum bonding applications, Wedge Bonding has evolved to accommodate various materials and alloys, even those like gold, previously believed to require heat for effective bonding.

Ultrasonic Bonding

Ultrasonic Bonding is a wire bonding process that applies ultrasonic energy and force over time to create a solid and reliable bond between two materials. Wire is pressed against the surface at low force and vibrated for a period of time to create the bond. Ultrasonic bonding generates minimal heat during the process. This is particularly beneficial for bonding temperature-sensitive materials or delicate components vulnerable to heat, as well as materials whose oxidation can accelerated by being exposed to heat.

Ball Bonding

Traditionally completed as a thermosonic process, Ball Bonding can also be adapted to work efficiently as an ultrasonic process. Force, time and ultrasonic settings may need to be increased to compensate for the lack of heat on the bond surface, but still be low enough to avoid part damage. For example, Ultrasonic Ball Bonding is used on plastic and flexible parts.

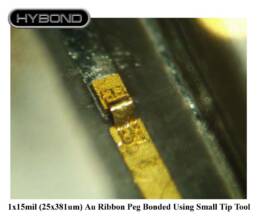

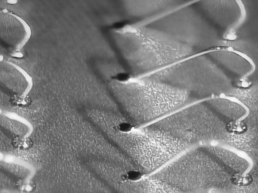

Peg Bonding

Peg Bonding has similarities with Wedge Bonding as it utilizes force, time, and ultrasonics at room/ambient temperature for bond formation. The key difference is a simplified wire handling process. In Peg Bonding, the wire or ribbon is not spool fed, but either pre-aligned over the bond pad, or manually introduced under the bonding tool (peg).