Specialized wire bonding and die bonding solutions

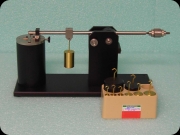

HYBOND Universal Wire Bonder Test Systems (DFS IV) and DFS Calibration Unit

Essential tools for monitoring and calibrating bonders

Designed to measure a wire bonder’s dynamic force and ultrasonic generator output in real-time for precise monitoring of your process.

The HYBOND Universal Wire Bonder Test System provides force information measured in grams and milliseconds as well as U/S power for performance monitoring and calibration, regardless of the bonder manufacturer’s make and model. For HYBOND wire bonders the DFS calibration procedure can measure and calculate U/S system power, frequency, phase and impedance.

- Manual, semi-auto and auto bonder compatible

- Force and voltage measuring modes

- Reference trace capture and storage

- Lightweight, compact and portable design

Easy set up for calibration, troubleshooting and training – anywhere.

The HYBOND Universal Wire Bonder Test System simplifies setup for measuring different wire bonders – by enabling users to match ultrasonic, time and force settings between machines – whatever panel setting and calibration differences.

Force waveforms represent the duration and magnitude of the bond head force to help identify potential issues such as head bounce, table vibration and force/time inconsistencies. In volts mode, waveforms can show consistency and power levels produced by the U/S system.

This precision device is used to calibrate the force sensors of the DFS IV Dynamic Force Measurement System.

HYBOND Universal Wire Bonder Test Systems (DFS IV) Features

- Works on manual, semi-auto and auto bonders

- Ambient temperature sensor

- Adjustable datum and cursor

- Reference trace capture and storage

- 10.1” touch screen display

- Universal power adapter for 110-240VAC

- Built-in USB 2.0 for external file storage

- Force and voltage measuring modes

- Force measurement displayed in grams

- Adjustable date/time and test machine information

- U/S measurements displayed in Watts for HYBOND wire bonders

HYBOND Universal Wire Bonder Test Systems (DFS IV) Specifications

- Total Force Measurement Range: 0g to 4Kg (limited by sensor force range listed below).

- Scope Force Range: 2g/div. to 1Kg/div. (9 ranges in 1-2-4 increase sequence).

- Total Volts Measurement Range: 0 to 200V.

- Scope Volts Range: 100mV/div to 50V/div (9 ranges in 1-2-5 increase sequence).

- Scope Lead Compatibility: Standard 1X and 10X oscilloscope leads for Volts mode operation

- Total Time Measurement Range: 0 to 20 seconds

- Scope Time Range: 1 µs/div. to 2 s/div (20 ranges in 1-2-5 increase sequence)

- Sensor Force Range: 10gr. to 1Kg. NOTE: Force sensor does not measure ultrasonics (U/S must be off or power setting must be 0 while measuring force with the DFS-IV).

- Temperature Range: Ambient or up to 160° C when using the high-temperature sensor.

- Maximum Sample Rate: 100 Mega samples per second.

- Data Transfer: Via USB 2.0 (2 outlets available).

- Input Power Requirements: 100 to 240VAC; 50/60Hz. @ 1.2A (Universal Power adapter).

- Unit Size: Length: 8.5” (21,6cm), Width: 11.1” (28,2cm), Depth: 2.1” (5,3cm).

- Unit Weight/Shipping Weight: 5.25 lbs (2,38Kg)/10 lbs (4,5Kg), shipping weight varies with options.

- Industry Standards: CE

Optional Features

- High-temperature sensor assembly rated to 160° C

- WST-15A-U (Work Stage) for holding sensors

- Calibration kit (ambient or high temperature)

- Extra sensors

Leading companies rely on HYBOND for technical assistance and support to help keep bonding operations running smoothly.

Dedicated as-needed Field Service

Our factory-based sales and support personal are trained in bonder maintenance and operation. If further on-site expertise is needed, we can deploy support personal worldwide to assist with anything from calibration and optimization to equipment maintenance.

Responsive troubleshooting and Technical Support

Our knowledgeable team is committed to helping you promptly – and free of charge via phone or e-mail. If the issue requires more hands-on attention, we can arrange an on-site service visit for resolution or repair.

Customized technical Training

Expand your expertise and essential skills through our wire bonding fundamentals course. Offered three times a year, and as part of tailored training for small groups, available on-site, or at our sunny California headquarters.

Trial samples and Applications guidance

Our multi-industry bonding experience can provide valuable insight into your specific application requirements. We can set up a trial bonds and help you determine the ideal wire or die bonder for your needs.