Specialized wire bonding and die bonding solutions

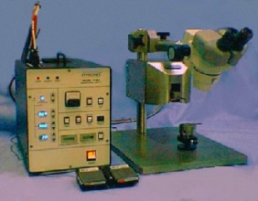

Model 616B-003 Digital Ultrasonic Peg Bonder

Designed for bonding applications without wire feeding

Bonding flexibility for a range of applications in medium to high volume production.

HYBOND Model 616B-003 is designed with the flexibility to take on a variety of bonding tasks including “tacking” tuning ribbons, insulated wire bonding, flex-on-flex bonding, pin tab bonding, mesh bonding and ball coining.

- Variable height bonding

- Ability to feed parts from multiple directions

- Multi-application flexibility

- Soft-Touch™ bonding for reduced damage

- Programmable bond schedules

Ideal for a wide range of interconnect bonding needs.

Model 616B-003 can easily adapt to different bonding tasks. When equipped with a HYBOND programmable motorized work platform, the 6161B-003 can be transformed into a semi-automatic machine enabling higher volume production. The separate bond head and control module provide the flexibility for use in confined spaces and can easily adapt to existing workstations. Separate components also offer the freedom to position the bond head on the workbench while placing the control module conveniently underneath.

Model 616B-003 Digital Ultrasonic Peg Bonder Features

- HYBOND Soft-Touch™ bonding technology for improved yields

- Servo-motor vertical (Z-axis) control

- 0.75” vertical bonding window

- Variable height bonding within 0.75”

- Search height adjustable in 0.001” increments

- Hi/Low Ultrasonic Power (PLL Generator)

- Digital Parameter adjustment in actual units

- Storage for up to 10 bond schedules

- Bond head separate from control module

- Dual bond counters for tool use & total bonds

- Dual footswitch control for vertical movement

- Fast or slow Z-axis movement in manual mode

- Bond level sensor system stops Z-axis movement upon contact with bond surface and activates bond cycle.

- Deep access when using 0.75" wedge

- Wiring for 120 VAC 50/60Hz @ 10A Max.

Model 616B-003 Digital Ultrasonic Peg Bonder Specifications

- Ultrasonic System: PLL self-tuning, 62.5 KHz (±2.5KHz) nominal

- Ultrasonic Power Range: 0-2 watt on Low setting, 0-4 watts on High setting

- Bond Time Range: 0 - 900 mSec

- Bond Force Range: 12 - 300 grams

- Bondable Wire Diameters: 0.7 to 3.0mil (18 to 76μm), may vary by material

- Bond Head Movement: True linear vertical (Z) motorized movement with fast and slow speeds in manual mode or search height pause in auto mode

- Bond Actuation: Sensor at variable height, actuated by contact with bond surface

- Input Power Requirements: 120 VAC 50/60 Hz @ 10A (std), order OP-12 for 240VAC 50/60Hz

- Min. Bench Space Required: 14" x 31" x 17" (36cm x 79cm x 43cm)

- Unit Weight /Shipping Weight: 70/150 lbs (31,8 / 68,2 Kg). Shipping weight varies with options ordered.

- Industry Standards: CE certified

Optional Features

- Leica S7E Zoom Stereo Microscope (OP-06S7E)

- Nikon SMZ745 Microscope (OP-06B)

- Dual Fiber Optic Illuminator (OP-08B)

- White LED Ring Illuminator (OP-08R1-LED)

- Provisions for 240VAC 50/60 Hz (OP-12)

- Beam Lead Diode Bonding option (OP-47)

- Base Plate & Post for mounting the bond head (when used as a tabletop unit as shown in the photograph) (OP-100)

- Microscope Boom Arm & Clamping Block for mounting the microscope to the post (see photograph) (OP-101)

- Work Stages: Heated & Unheated available

- PT-X.X: Peg Tool as ordered per application

Leading companies rely on HYBOND for technical assistance and support to help keep bonding operations running smoothly.

Dedicated as-needed Field Service

Our factory-based sales and support personal are trained in bonder maintenance and operation. If further on-site expertise is needed, we can deploy support personal worldwide to assist with anything from calibration and optimization to equipment maintenance.

Responsive troubleshooting and Technical Support

Our knowledgeable team is committed to helping you promptly – and free of charge via phone or e-mail. If the issue requires more hands-on attention, we can arrange an on-site service visit for resolution or repair.

Customized technical Training

Expand your expertise and essential skills through our wire bonding fundamentals course. Offered three times a year, and as part of tailored training for small groups, available on-site, or at our sunny California headquarters.

Trial samples and Applications guidance

Our multi-industry bonding experience can provide valuable insight into your specific application requirements. We can set up a trial bonds and help you determine the ideal wire or die bonder for your needs.