Specialized wire bonding and die bonding solutions

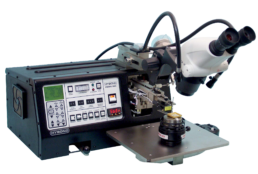

626 Multipurpose Digital Thermosonic Bonder

All-in-one versatility for precise ball, wedge, bump/stud and peg bonding applications.

Designed for deep-access and long-reach performance with the ability to operate as a ball, wedge, bump/stud or peg bonder.

The HYBOND Model 626 Multipurpose Bonder is an all-in-one solution for a wide range of applications. The 626 is ideal for challenges that require bonding at extreme height differences between the first and second bond, and for bonding wires or ribbons to sensitive devices such as gallium arsenide FET’s, MMIC’s and LED’s.

- Ball, wedge, bump/stud or peg bonding capability

- Deep-access – long-reach versatility and precision

- Soft-Touch™ bonding for reduced damage

- Programmable bond schedules

Multipurpose flexibility to easily change from ball bonder to wedge bonder at the touch of a button and change of the tool.

The HYBOND Model 626 Multipurpose Bonder offers performance versatility to address unique and evolving applications and demanding requirements. Industry-leading features enable ease of use to give operators precise control – in ball, wedge, bump/stud or peg bonding mode.

HYBOND Soft-Touch™ bonding technology provides added control to reduce the risk of damage to delicate components. Model 626 also offers the option of programmable motorized X-Y operation with OP-54 or pick, place and bond performance features with OP-47A.

Model 626 delivers precise and reliable bonds with wire diameters ranging from 0.7 to 2.0 mil (18 to 51µm) gold wire, when in ball bonder configuration, or 0.5 to 3.0 mil (12 to 76µm) and ribbon up to 1.0 x 12.0 mil (25 x 300µm) when in wedge or peg bonding mode.

HYBOND Model 626 Features

- HYBOND Soft Touch™ bonding technology for improved yields

- Programmable, saveable bond schedules and adaptable reset heights

- Auto-stitch or manual continuous stitch modes for wedge bonding

- Safety or reverse bonds for ball bonding

- Touch sensor-controlled bond actuation for variable bonding height

- Deep vertical access and a wide bonding window for added applications

- Digital temperature controller and high/low power PPL ultrasonic generator

- Convenient swing-away wire/ribbon clamp assembly

- Inertial .5” and 2” spool mounts and motorized feed for superior wire control

- Precise z-axis control

- Optional programmable motorized X-Y operation

- Expandable pick, place and bond performance

Model 626 bonds gold and aluminum wire and ribbon, and in some applications copper, silver, palladium-silver and up to 1.5 mil platinum wire.

HYBOND 626 Multipurpose Digital Thermosonic Bonder Specifications

- Ultrasonic System: PLL self-tuning, 62.5 KHz (±2.5KHz) nominal

- Ultrasonic Power Range: 0 - 0.2 watts low setting, 0-2 watts high setting

- Bond Time Range: 0 - 900 mSec

- Bond Force Range: 12 - 250 grams

- Temperature Control Range: Ambient to 250° C

- Bondable Wire Diameters: Ball configuration 0.7 to 3.0 mil (18 to 76µm), Wedge or Peg configuration 0.5 to 3.0 mil (12,7 to 76µm)

- Bondable Ribbon Dimensions: Up to 1 x 20 mils (25,4 x 510 µm) in wedge or peg bonder mode.

- Bondable Wire/Ribbon Materials: Ball bonding mode: Gold and Platinum wire. Wedge bonding mode: Gold, Aluminum, Copper, Silver, Platinum

- Bond Head Movement/Reach: Motorized (servo). Activated by manipulator mounted switches or foot switches. Horizontal reach up to 6.5in (165mm)

- Bond Actuation/Height: By sensor at bond surface contact

- Z Axis Travel: 0.75 in (1,90 cm)

- Vertical Bonding Window: 0.74 in (1,88 cm)

- Table Motion: 4:1, manual manipulator, standard

- Input Power Requirements: 90-260 VAC 50/60 Hz @ 10A max

- Minimum Bench Space Required: Width: 25in.,

- Depth: 30in. (63,5 x 76,2cm).

- Unit Weight /Shipping Weight: 70 /150 lbs (31,8 / 68,2 Kg). Shipping weight will vary.

- Vacuum Requirement: Vacuum = 20 inHg min. (only for use with work stage if needed).

- Industry Standards: CE certified

Optional Features

- OP-06B: Nikon SMZ745 Stereo Microscope

- CCTV-XX: Microscope, Camera, Monitor, etc.

- OP-08A-LED: Dual Fiber Optic Illuminator

- OP-08R1-LED: White LED Ring Illuminator

- OP-30A: 8:1 X-Y Manipulator

- OP-31: Tool Heater and Temp. Controller

- OP-47A: Beam Lead/Die Pick, Place & Bond

- OP-54: Motorized X-Y and Y Step Back

- OP-06B: Nikon SMZ745 Stereo Microscope

- CCTV-XX: Microscope, Camera, Monitor, etc.

- OP-08A-LED: Dual Fiber Optic Illuminator

- OP-08R1-LED: White LED Ring Illuminator

- OP-30A: 8:1 X-Y Manipulator

- OP-31: Tool Heater and Temp. Controller

- OP-47A: Beam Lead/Die Pick, Place & Bond

- OP-54: Motorized X-Y and Y Step Back

Leading companies rely on HYBOND for technical assistance and support to help keep bonding operations running smoothly.

Dedicated as-needed Field Service

Our factory-based sales and support personal are trained in bonder maintenance and operation. If further on-site expertise is needed, we can deploy support personal worldwide to assist with anything from calibration and optimization to equipment maintenance.

Responsive troubleshooting and Technical Support

Our knowledgeable team is committed to helping you promptly – and free of charge via phone or e-mail. If the issue requires more hands-on attention, we can arrange an on-site service visit for resolution or repair.

Customized technical Training

Expand your expertise and essential skills through our wire bonding fundamentals course. Offered three times a year, and as part of tailored training for small groups, available on-site, or at our sunny California headquarters.

Trial samples and Applications guidance

Our multi-industry bonding experience can provide valuable insight into your specific application requirements. We can set up a trial bonds and help you determine the ideal wire or die bonder for your needs.