Specialized wire bonding and die bonding solutions

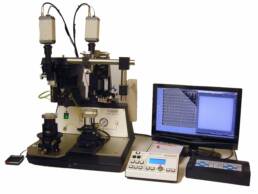

EDB-141 Epoxy Die Bonder

Die placer with programmable pattern dispense and precise bond-like thickness control

Ideal for multi-chip modules and batches in lab or production applications

Two-camera system increases productivity by 2X or more over competitive models. During die placement, the operator can simultaneously target the next die at pick-up location.

This machine includes package depth sensing for precise bond line thickness control regardless of package and epoxy variants.

- Manual and semi-automatic operation

- Patented bond-line thickness control

- Programmable dispense parameters and patterns

- Large format versions available

Manual or semi-automatic operation with remote control.

Standard EDB-141 features include a dual-screen CCTV system for enhanced visibility, package depth sensing for consistent bond line thickness and built-in programmable dispensing control for precise positioning and bonding.

The EDB-141 can be fitted with waffle pack/gel pack, loose die pedestal, or die ejector for added performance flexibility.

Model EDB-141 Epoxy Die Bonder Features

- Dual-screen CCTV visual targeting system

- Package depth sensing for consistent and precise bond line thickness

- Built-in programmable dispense patterns and control

- Storage for up to 200 dispense programs

- Multiple programmable dispense patterns and placement positions

- Motorized/programmable X-Y stage

- Waffle pack/loose die pickup pedestal

- Pitch and Roll adjustments for bond head

- Custom die collets to match customer die

- Manual and semiautomatic operation modes

- Remote control panel for ease of operation

- Footswitch operation allows hands-free pick and place operation

Model EDB-141 Epoxy Die Bonder Specifications

- Dispense System: Programmable pressure, time and drip avoidance system.

- Bond Line Accuracy: ±.0.5 mil (±m12,7 lµm)

- Temperature Control Range: Ambient to 250° C with optional heat stage.

- Bondable Die Size Range: 6x6 mils (152x152 µm) to 1x1 inch (25x25 mm) standard

- Placement Accuracy: ± 1 mil (25,4 µm) standard. Less when adding microscope option.

- Dispense Materials: Epoxy, conductive epoxy and silver glass.

- Bond Head Actuation: Motorized, rotational, w/ fixed pick-up and placement points.

- Bond Actuation: By opto-sensor at fixed height. Cycle initiated by footswitch.

- Vertical Bonding Window: 0.5” (1.20 cm) / 0.125” to 0.500” (0,31 to 1,20 cm).

- Table Motion: 1.9" (48mm) travel standard. (5" travel optional)

- Input Power Requirements: 120 VAC 50/60 Hz @ 10 amps. 240VAC requires PN 600-065

- Min. Bench Space Required: Height/width: 24” (45cm), Depth: 22” (56cm), without monitor.

- Facilities Required (min.): Vacuum: 23”Hg (584mmHg). Air: 60-80psi (4.2Kg/cm3).

- Unit Weight /Shipping Weight: 75lbs (34Kg)/150lbs (68Kg). Shipping weight will vary.

- Approx. Units Per Hour (UPH): 90 -240 depending on options, settings and mode of operation.

Optional Features

- Die Ejector Systems

- Vacuum die pedestal for gel packs

- Side-viewing Stereo Microscope w/ Swivel Base

- Dual fiber-optic illumination system

- Stir column for silver glass /conductive epoxy

- Micro-Dispensing head

- Lead frame indexing systems

- Semi-automatic indexing systems

- Heater stage and temperature controller

- Customization based on specific application

Leading companies rely on HYBOND for technical assistance and support to help keep bonding operations running smoothly.

Dedicated as-needed Field Service

Our factory-based sales and support personal are trained in bonder maintenance and operation. If further on-site expertise is needed, we can deploy support personal worldwide to assist with anything from calibration and optimization to equipment maintenance.

Responsive troubleshooting and Technical Support

Our knowledgeable team is committed to helping you promptly – and free of charge via phone or e-mail. If the issue requires more hands-on attention, we can arrange an on-site service visit for resolution or repair.

Customized technical Training

Expand your expertise and essential skills through our wire bonding fundamentals course. Offered three times a year, and as part of tailored training for small groups, available on-site, or at our sunny California headquarters.

Trial samples and Applications guidance

Our multi-industry bonding experience can provide valuable insight into your specific application requirements. We can set up a trial bonds and help you determine the ideal wire or die bonder for your needs.